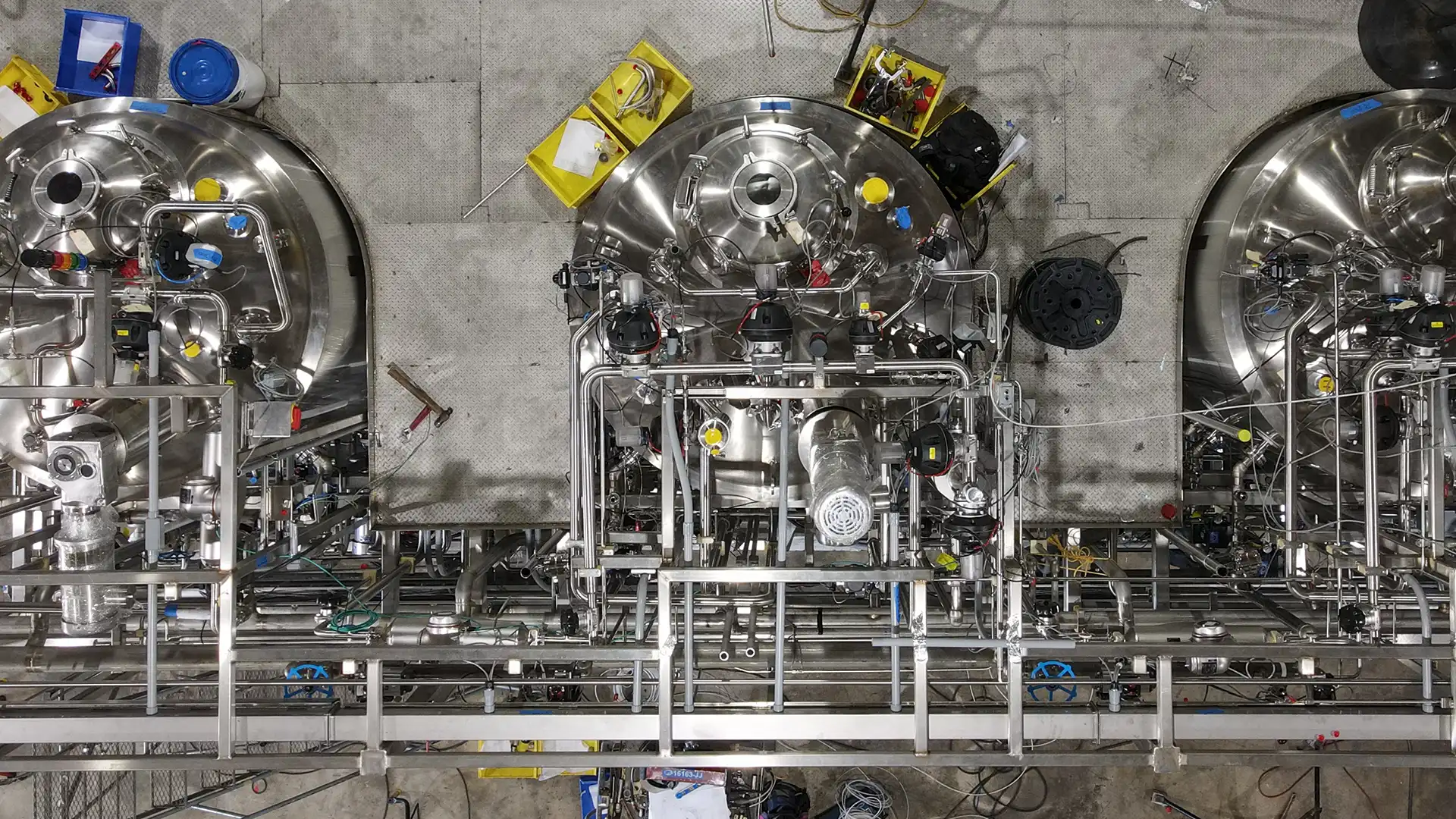

Industrial Process Piping

UPSi is the premier sanitary orbital welding, process, utility, and mechanical contractor in the industry.

Safety

At UPSi, safety is personal. Working side-by-side everyday with our colleagues means that we grow to become more than a team, we become friends and family. Caring for one another is at the core of a successful Safety Program. All of us at UPSi care for each other to ensure that all of us return home safely at the end of each day.

Our commitment to safety begins at the highest levels of the organization. Our Safety Manager oversees the implementation of the Safety Program throughout the project portfolio.

Safety Officers dedicate their efforts to training, compliance, and oversight at each project. Each individual team member is an active participant for ensuring that safety measures are in place at all times during execution.

This commitment to safety has given UPSi one of the best safety records and has allowed us to achieve exception safety performance in industrial process piping.

Quality

UPSi offers full Quality examination and inspection services. These services are executed by our team of Quality Inspectors and include weld boroscoping, visual examinations, material inspections, slope verifications, weld log documentation, welder certifications, and complete systems turnover package documentation.

Our Quality Manager oversees the implementation of the Quality Management Program on all projects and assures that the quality of our fabrications, installations and services meet or exceeds industry standards and the requirements of our clients.

High Purity Piping

UPSi is the premier sanitary orbital welding, process, utility, and mechanical contractor in the industry.

Our orbital welders are uniquely qualified for all sanitary 316L stainless steel, AL6XN alloy, Hastelloy C22 alloy, and many other specialty alloy systems.

Our expertise in fabrication and installing high-purity process, water, chemical and gas piping systems include:

- Sanitary Process Piping Systems

- Clean-in-Place Systems

- Water for Injection Systems

- Sterilize-in-Place Systems

- Hot Water for Injection Systems

- Chemical Systems

- Process / Utility Skids Interconnect Piping

- Process Waste Systems

- Utility Piping Systems

- Oxygen / Nitrogen / Carbon Dioxide Gas Systems

- Instrument Air and Compressed Air Systems

All fabrications and installations are conducted in accordance with the requirements of ASME Section IX and ASME B31.3 for Process Piping.

General Mechanical

UPSi provides exceptional service in the manually welded, non-hygienic systems. Our expertise in fabrication and installing stainless steel scheduled pipe, carbon steel, copper, and lined-double contained systems include:

- Chill Water Systems

- Steam / Condensate Systems

- Potable Water

- Compressed Air

- Vaccuum

- Waste Treatment and Storage

- Oxygen / Carbon Dioxide / Other Gas Systems

Shop Spool Fabrication

UPSi maximizes productivity and quality by fully utilizing our shop pre-fabrication capabilities. Our philosophy of applying an “assembly line” approach to spool fabrication has led to high quality and high productivity. This in turn has allowed us to maintain a low average cost per weld produced and reduce overall project schedule.

Our clients can also expect to find the same rigorous safety standards applied in all of our shop locations as would be implemented at any client location.

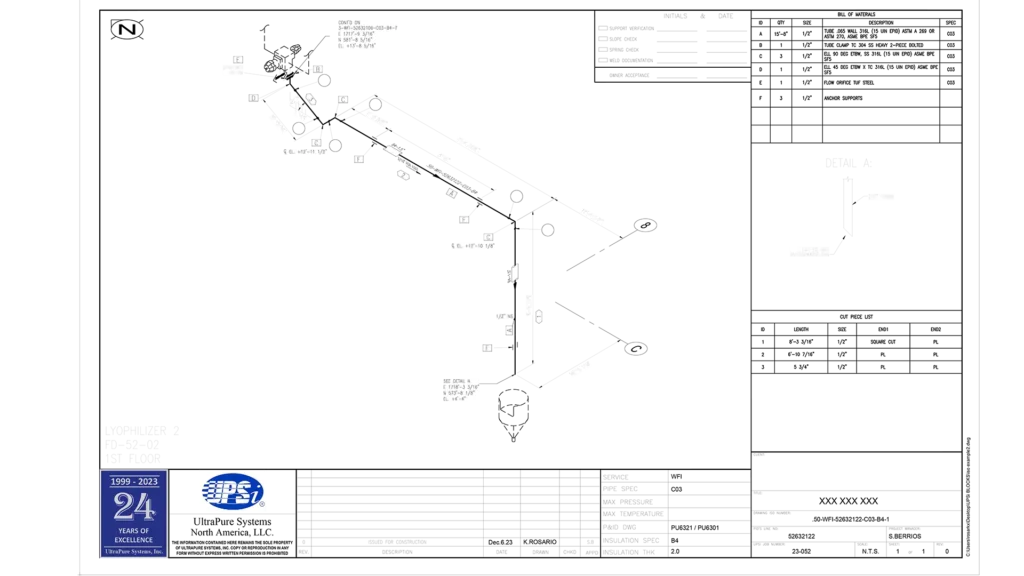

3D Modeling and Isometric Extraction

UPSi uses 3D Plant Design Software to design, model and document process piping systems. Specification-driven design and standard parts catalogs streamline the placement of piping, equipment, and support structures. Next, we extract the design from the 3D model to extract Issue-for-Construction Isometric drawings.

All isometric drawing are accompanied with weld logs to document all welds and complement the implementation of our Quality Management Program.

Why Choose UltraPure Systems, Inc

We continuously strive to provide the best quality solutions for our clients using the latest available technologies and equipment.

Safety Prioritized

All our employees and solutions prioritize safety from start to finish.

Top Quality

Providing state-of-the-art solutions and versatility.

Best Service

Lifelong collaboration with our clients.

Cost Effective

We strive to meet your budget needs while maintaining quality and schedule.

Experienced

Celebrating 25 years of business!